| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | YH PIONEER |

| Price : | To be negotiated |

| Payment Terms : | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability : | 30 Sets/month |

| Delivery Time : | To be negotiated |

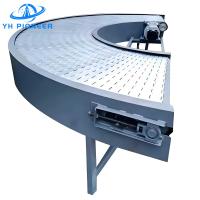

Durable Stainless Steel Bottle Conveyor System for 1890N Working Load and 500mm Minimum Back Radius

Bottle Conveyor Systems

We provide professional Chain Plate Turning Conveyor System that can accurately and efficiently stack and arrange goods, significantly improving the operational efficiency of warehousing and logistics.

The Bottle Conveyor Systems are designed to handle the transportation of bottles with precision and efficiency. These systems are customizable and adaptable to various bottle sizes and shapes, ensuring a seamless integration into existing production lines. The design philosophy behind Bottle Conveyor Systems is to provide a reliable, low-maintenance, and high-performance solution for bottle handling in industries such as beverages, food, and pharmaceuticals.

TECHNOLOGICAL ADVANTAGE

Pressureless Conveying: Utilizes a specially designed differential speed bottle conveyor

frame and guards, controlled by advanced programmable logic

controllers and frequency converters for automatic speed

adjustment, ensuring bottles are conveyed without pressure,

reducing the risk of damage.

High Speed, Low Energy Consumption, High Efficiency: With an efficiency rate of over 99%, the system operates without

bottle collisions, saving on labor costs, and can be integrated

into a pressureless line solution.

Electrical Control: Equipped with photoelectric detection points along the production

line, allowing for the setting of operational parameters to adjust

the running state (speed and spacing) as needed.

PRODUCT SPECIFICATIONS

Chain Type: Customizable to meet specific operational requirements.

Plate Width: 83.8mm, suitable for a broad range of bottle sizes.

Working Load: 1890N at 21°C, indicating the system's capacity to handle

substantial weights.

Back Radius (Minimum): 500mm, facilitating smooth transitions and turns in the conveyor

path.

Backflex Radius (Minimum): 130mm, allowing for compact design in areas with limited space.

Weight: 2.13Kg/m, reflecting the system's robust construction and

durability.

PRODUCT MATERIALS

Conveyor Belt: Made from durable materials such as PVC, PU, or other suitable

plastics to ensure longevity and hygiene.

Frame: Constructed from stainless steel or carbon steel for a robust and

reliable structure.

Drive System: Includes high-quality motors and reducers to ensure efficient

power transmission and smooth operation.

Guide Rails: Designed to securely guide bottles along the conveyor path,

preventing misalignment and ensuring smooth transitions.

PRODUCT APPLICATION

Conveyor Belt: May consist of plastic chain plates, mesh chains, rollers, or

belts, designed to ensure bottle stability during transportation.

Guide Rail System: Used to direct bottles along a predetermined path, which can be

straight or curved.

Drive System: Comprises motors and reducers, responsible for driving the

conveyor belt.

Control System: PLC-controlled, capable of integration into automated systems for

precise control.

Buffer Devices: Designed to reduce collisions and friction between bottles,

especially at high speeds.

SERVIC and SUPPORT

We provide comprehensive maintenance services to ensure the Bottle

Conveyor Systems remains in optimal condition. Our dedicated

support team is available to assist with any technical queries or

service needs.

PRODUCT PARAMENTERS

| Chain Type | Customizable |

| Plate Width | 83.8mm |

| Working Load | 1890N(21℃) |

| Back Radius(min) | 500mm |

| Backflex Radius(min) | 130mm |

| Weight | 2.13Kg/m |

*It can be modified according to customer requirements.

Please click the form below to download and fill it out to inquire

about detailed specifications and parameter options.

ORDER PROCESS

|