| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | YH PIONEER |

| Price : | To be negotiated |

| Payment Terms : | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability : | 30 Sets/month |

| Delivery Time : | To be negotiated |

High - Friction Buckle Chain Turning Conveyor Plate Surface TPE

with Bearings for Reliable Material Handling

Buckle Chain Type Turning Conveyor Plate Surface TPE with Bearings

We provide professional Buckle Chain Type Turning Conveyor Plate

Surface TPE with Bearings, support the conveying of various types ,

and provide a variety of conveying types.

The Buckle Chain Type Turning Conveyor Plate Surface TPE with

Bearings is a specialized conveyor chain designed for applications

that demand high wear resistance and low noise operation. This

chain is particularly well-suited for spiral turning conveyance in

industries such as food and beverage, where hygiene and gentle

handling are critical.

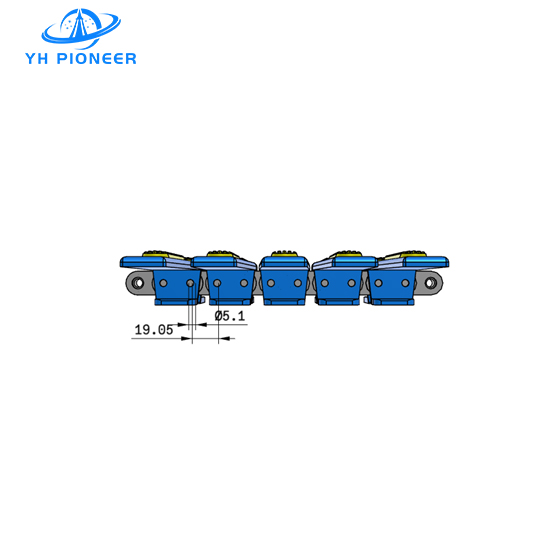

PRODUCT PARAMENT

Product name | Buckle chain type turning conveyor plate surface TPE with bearings |

Application | Mainly suitable for spiral conveyors. |

Material | Card board material: blue polyoxymethylene (POM), orange rubber on the surface, operating temperature -30°C~+80°C |

Base Chain | Standard 12A roller chain, material: carbon steel, stainless steel |

Maximum Speed | 50 m/min lubricant ; 30 m/min dry |

Working load | Carbon steel working load is 3200N, stainless steel working load is 1600N |

Maximum conveying total length | 30M for carbon steel and 24M for stainless steel |

Package | Each length is 1.524M |

| opposite bending raduis | 150 mm |

| opposite bending raduis | 610 mm |

| Base chain material | Carbon steel |

*It can be modified according to customer requirements.

Please contact us for the latest specification stock and quotation

PRODUCT ADVANTAGE

* High Wear Resistance: The TPE surface enhances the chain's durability and reduces

friction, suitable for heavy-duty conveying tasks.

* Low Noise Operation: The rubber surface helps to absorb vibrations, ensuring a quieter

operation.

* Customizable Design: The height and form of the flights can be adjusted to meet

specific material handling requirements.

* Temperature Adaptability: The POM material ensures reliable performance across a wide

temperature range.

* Enhanced Friction: The TPE surface provides additional grip, reducing the risk of

product slippage during turning and elevation.

* Durability: The combination of POM and TPE materials ensures the chain is

long-lasting, even under continuous operation.

* Maintenance Friendly: The modular design allows for easy replacement of individual

components, reducing downtime and maintenance costs.

* Versatility: The chain's design can be customized to fit various production

line layouts and requirements.

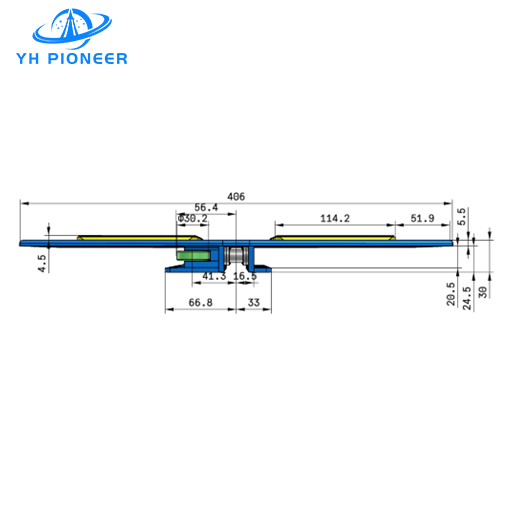

PRODUCT SPECIFICATIONS

* Product Name: Buckle Chain Type Turning Conveyor Plate Surface TPE with Bearings

* Application: Ideal for spiral turning conveyance in the food and beverage

industry.

* Belt Material: Polyoxymethylene (POM) with a temperature range of -30°C to +80°C.

* Pin Material: Polypropylene (PP).

* Belt Load: Capable of withstanding a load of 8800 N per meter at 21°C.

* Belt Color: Blue with an orange TPE surface.

* Standard Module Width Multiplier: 1.

* Belt Width: 304.8 mm.

* Center Distance Between Flights: 38.1 mm multiplied by the number of standard modules.

* End Face to Flight Distance: 25.2 mm.

* Weight: 5.77 kg/m².

* Reverse Bending Radius: 150 mm.

* Minimum Turning Center Radius: 610 mm.

PRODUCT MATERIALS

* Chain Plate: Made from POM, known for its wear resistance and self-lubricating

properties.

* Flights and Sidewalls: Constructed from the same POM material for consistency and

durability.

* Bearing Material: May include POM or 6200Z (bearing steel) for high load-bearing

applications.

PRODUCT APPLICATIONS

* Food Processing: For the gentle and hygienic transport of food products through

turns and spirals.

* Beverage Industry: Suitable for handling glass bottles, cans, and other containers in

high-speed turning and long-distance conveying lines.

* Pharmaceutical and Chemical Industries: Capable of handling small containers and vials with precision and

care.

ORDER PROCESS

|